Hi,

It has been a busy day. I made the most of dry weather this morning to do some outside carpentry to mount the screen we will use to display the timetable to our audience. The screen is an old 15 inch one that my wife used to use before a new widescreen edifice took its place. A frame that allows us to attach it to the front of the layout but angled upwards gives us the ability to display information without distracting too much from the layout itself.

David has been doing a large amount of work on the timetable itself based on some real items for Pwllelli - Llangerisech's mythical neighbour! A concoction that is based on a semblance of reality helps us place the layout and lends a sense of purpose. Trains will be shown along with their destination or origin. The first picture shows things mocked up, but gives no idea of the amount of time that David has devoted to researching this and coming up with a workable item.

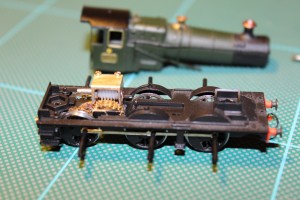

Once back inside, the last bits of the Collett Goods were put together. The tender uses the Association 8mm driving wheels with extended axles, but with the extensions turned down. On the old Manor models, a phosphor bronze strip had indentations in the form of cups, so the extensions were turned to points. On the newer version fitted to the 28xx and new Manors, the strip has changed to one with holes. The result of this is that the points need to be turned accurately to 1mm diameter. This has the benefit of extra sideplay, but means that a lathe is really needed to do the conversion. However, the lathe time was less than half an hour for me.

The chassis and wheels have all be painted, so it was really just a bolt and fit together job. The main advantage of the design is the ability to build then separate the worm carrier, so once the centres are established very little fettling is needed. In fact this one went together first time, so the measurements must have been accurate.

The intermediate gear (30:1 plus a 16 tooth gear) was mounted on stub axles and the rear wheels and final gear (20 tooth) mounted then checked. All OK, so the worm carrier could be fitted and the gear train checked throughout. Removing the worm carrier and completing the other axles allows the quartering and coupling rods to be sorted with all the gears turning.

The body required some plastic removing from around the firebox area to allow the drive shaft from the tender to pass through. All that remains to do is to finish soldering the crank pin washers, fit the driveshaft and bolt the body on with a new tender drawbar. The final picture is just a dummy - you will have to come to Aldershot this weekend to see if it runs OK!