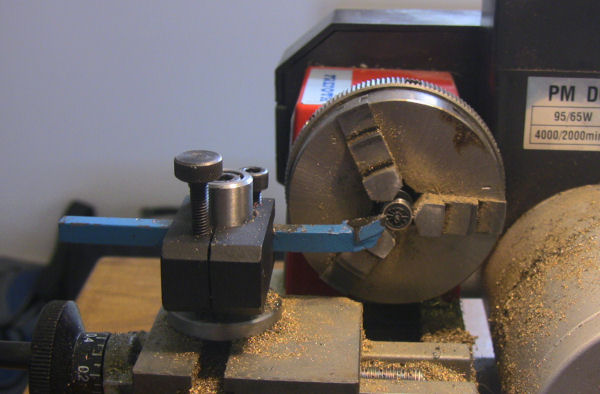

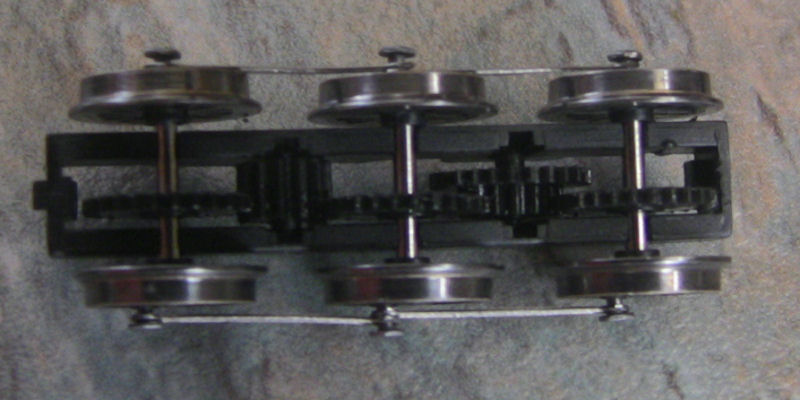

At our group meeting on Saturday Nigel kindly turned the wheels of the Terrier down to finescale standards.

There wasn't much to come off but the result is certainly worth it.

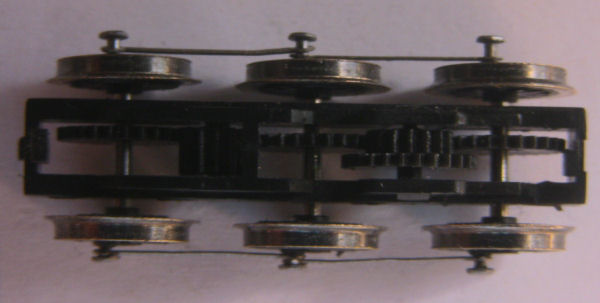

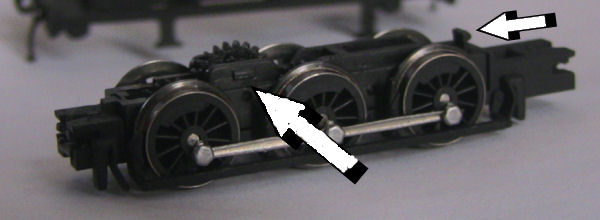

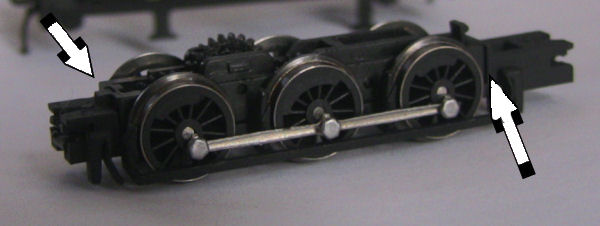

You can see from the above picture how flimsy the Dapol coupling rods are! The chassis is fully geared so the rods just go along for the ride which was lucky because the Dapol wheels slipped on their axles during the above process and needed re-quartering. In this case it is sufficient to get them close enough.

As well as straightening the coupling rods (again) I also need to reduce the height of the crank pins on one side which you will see refused to go in to the wheel as much as they did on the other side. Getting the pins in was difficult until Guy showed me a trick for holding small items using double sided tape stuck to the end of a pointed object.

When set to 9.42mm gauge the wheels just foul the plastic brake rods which will need to be filed, but only a little as they do a good job of keeping the wheels central without having to add any washers.

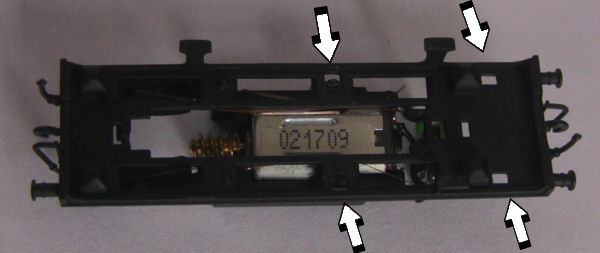

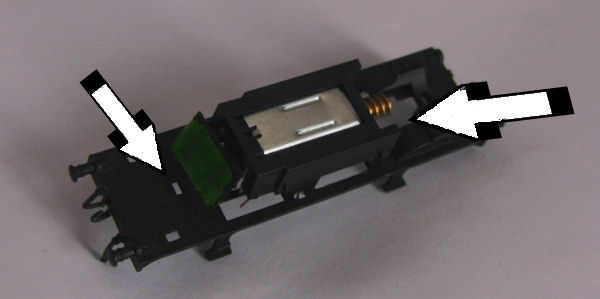

It looks as if the body will escape without any surgery. I have reassembled the chassis and found it impossible so far to get the front pickups in contact with the wheels - it is necessary to spring them out of the way when re-fitting the wheels and this is enough to make them lose contact. I will have to think about this...

I have also added a chip (CT DCX74z) which, although it replaced the resistor board, now intrudes quite noticeably into the cab. I may have a go at re-soldering the wires to the motor in a neater fashion which may save me a bit of space.