Evening. Continuing the countdown to the AGM and exhibition at Aldershot on the 11th, here's today's update.

No Cambrian layout can ever have too many 0-6-0 goods locos and that's quite handy when looking for building simple locos that run well. I have already done a conversion on the Peco Collett using my now proven solid split brass chassis method and using the original tender, but cut down to the correct height. For this second version, the loco chassis is identical to the first, but I will use a Dapol tender. The loco body is one aquired from Peco by Roger Jones, so none of the mechanism is thrown away this time.

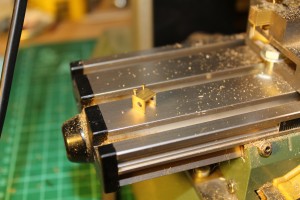

So in the Proxxon MF70 mill goes the brass rod and plate. These are drilled and screwed together before the holes for the bolt bushes are drilled. This is shown in the main picture. These holes start as 0.8mm to allow the plate is tapped for 14BA screws. The holes in the block are then enlarged to 1.6mm and a recess of 2.5mm to take the bushes. The bushes are the ones developed for the Manor chassis kit, so anyone who has built one will know what I am on about.

Once the two parts are secure, the axle holes are drilled to accept 2mm Scale Association bearings. Next the block will be milled to allow the muffs and gears room to move.

I will do another post to show the progress on this. It may seem a risk to be making a chassis this close to the show, but it is a copy of a proven design, so fingers crossed.

The second photo shows the worm mount part of the gearbox which will screw into the top of the main block. This method has the advantage of being able to quickly split the two parts when getting wheels quartered and gears meshed correctly. The box is milled out of solid brass and will take Association bearings in the large holes.