Realising that the tenth anniversary of his joining the 2mm Association was fast approaching without having actually finished any of his various layouts, Richard set himself the challenge of completing one - a scenic test-track layout - by the April meeting.

As I will have been a member for a quarter of that time, I have set myself a suitably scaled-down challenge. Starting something similar from scratch - a small scenic test track - and getting a quarter of it finished. Temptations to get half of it half-finished instead will be resisted...

Initial plans were to use the infamous IKEA Lack shelf, but second thoughts suggested this was not going to be easy to bring to Uckfield by train, so I looked instead to some of the recent "layout in a box" blogs on RMWeb - in particular "Paddock Wood Bay in a Box" by BCNPete (or should it be LGWPete now?) and "Box in a Box" by Scanman. Three large box files ("foolscap" officially, but actually a bit larger) were purchased.

Unfortunately my proposal at a recent meeting that the WAG should jointly purchase a laser cutter (suitable for cutting plywood for baseboards) met with complete lack of interest. I am sceptical that my limited woodworking skills would cut plywood to the required level of accuracy, and together with the potential for weight-saving that turned my attention towards foamboard for the surface.

Suitable wooden strips are available for making the frames, where I felt foamboard would be too fragile, and I finished up with a 700mm x 500mm sheet of 3.2mm foamboard (sufficient for four baseboards of approximately foolscap size), together with a pack of obeche strips of 12mm x 5mm cross-section. A mitre box to help cutting the corners, some small brass hinges, glue, and a roll of cork completed my list of purchases for the project.

The intention is to have two pairs of baseboards, each pair hinged together to help with the alignment. The problem of linking together the two pairs has been deferred for later (shallow baseboards won't allow much space for manipulating screws, dowels etc). For this semi-official Challenge entry I intend to concentrate on getting one pair of baseboards linked together, with one of them (approximately a quarter of the total) completed to the stage of track laid, scenery added, backscene in place (and maybe even painted).

I am currently planning on having one boxfile for each hinged pair of baseboards, thus allowing a depth of about 32mm for each baseboard, of which about half will be taken up by framework, foamboard, cork etc, leaving about half free for scenery. This should allow fences to be included, but not buildings - people are borderline, as the clearance will probably reduce as backscenes will eat into that space.

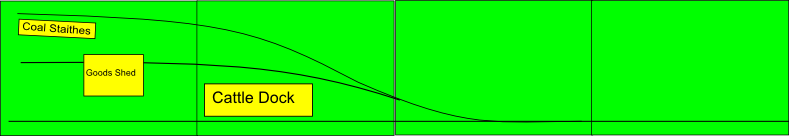

Availability of stock, buildings, people and other scenery suggests that a goods yard would be the obvious candidate as the subject of the model.

Track will be Easitrac - though that won't be very obvious if I stick to my target era of about 1905, when track ballast was generally topped with a layer of cinders which completely hid the sleepers. Probably at least part of the track would have been fully inlaid, to provide a convenient access route for road vehicles (horses and carts).

As currently planned, I intend to concentrate on the left hand half of the "layout", specifically the left hand half of that (which postpones the construction and installation of turnouts until the next section). Looking further ahead, the right hand end will probably be lowered slightly, and used as a base for cassettes, rather than as a conventional baseboard.

Construction of baseboards is well advanced, but it's a fairly slow process as the glue needs to be left overnight to set, and I prefer to do one (or occasionally two) side(s)/end(s) at a time.

Next I need to hinge two baseboards together. If I have my geometry right, the hinges will project slightly below the bottom of the baseboards, so I will need to add some small feet/legs to keep the hinges from scratching the surface on which the baseboards rest.

I am hoping that I can use the hinges to carry current between adjacent baseboards - if this doesn't provide a reliable contact, at least it should be possible to use flexible wires near to the hinges, rather than needing a plug/socket system.

Despite Nigel's advocacy of DCC (and effective demonstration of it on Llangerisech), I am intending to start with DC, and this will be a fairly unsophisticated "one engine in steam" operation (which also provides an excuse for lack of signals). Probably no need for separate isolated sections, even with DC.

David